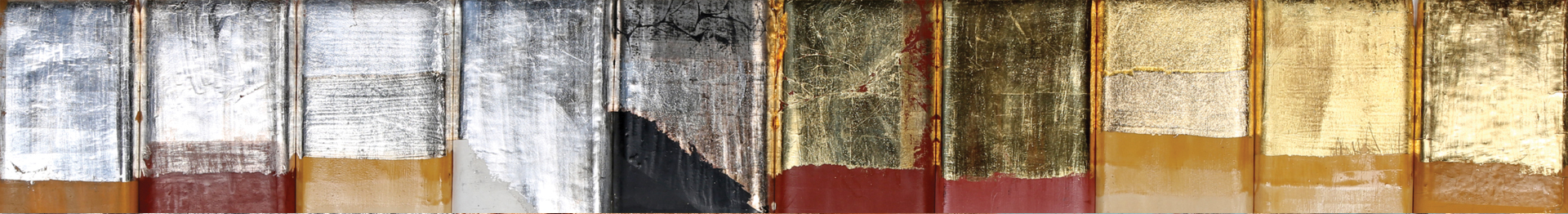

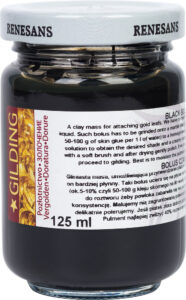

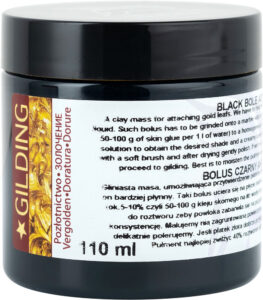

Red bole |

Yellow bole |

Black bole |

White bole |

Ammanitura |

Red acrylic bole |

Yellow acrylic bole |

Black acrylic bole |

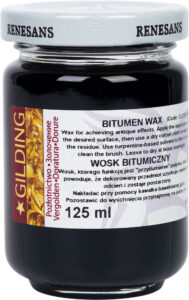

Bitumen wax |

|

Mikstion on varnish 3h |

Mikstion on varnish 12h |

Mikstion on spirit |

Waterbased mikstion |

Mecca varnish colourless |

Mecca gold varnish |

Varnish alcohol based |

Lustrina varnish |

Liquid bitumen |

Water based liquid bitumen |

Solvent for shellac |

Liquid shellac |

Dewaxed liquid shellac |

||

Bleached shellac |

Yellow shellac type "lemon" |

Light ruby shellac |

Dark ruby shellac |